Sedelon Heat Treatment Introduction

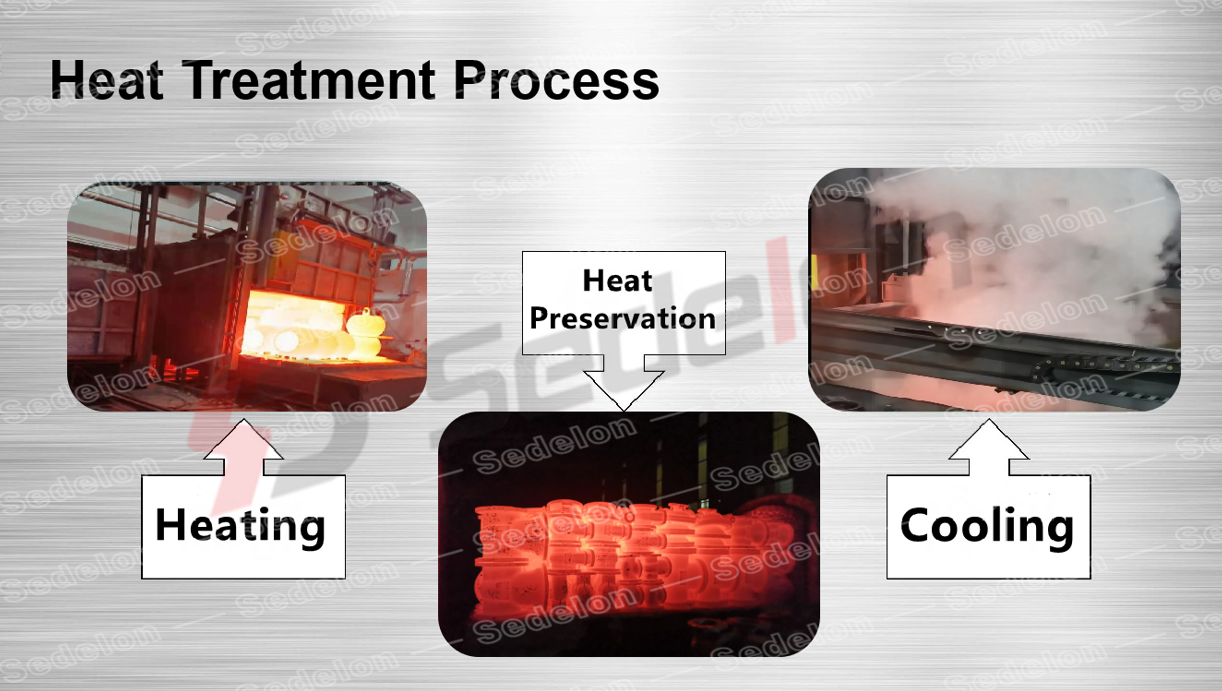

Heat treatment is a metal thermal processing technology which can realize the material that in solid state to obtain the expected structure and performance through the means of heating, heat preservation and cooling, that is, to improve the internal quality of the work-piece.

Heat treatment generally does not change the shape and the overall chemical composition of the work-piece. It will endow or improve the performance of the work-piece by changing the internal micro-structure of it or the chemical composition of its surface.

Integral

heat treatment is widely used in the treatment of valves and their accessories.

Its mainly process is heating, heat preservation and cooling.The quality of

this process determines the final heat treatment effect.

The integral heat treatment roughly has annealing, normalizing, quenching and tempering four basic types.

1. Quenching

Quenching has the shortest cooling time, usually cooling with cold water or oil.

2. Normalizing

Its cooling rate is between quenching and annealing, generally by air cooling. Normalizing can refine the crystal grain of steel during the slightly faster cooling, which can not only obtain satisfactory strength, but also significantly improve the toughness and reduce the cracking tendency of the work-piece.

3. Annealing

Its cooling speed is the slowest, generally through furnace cooling. The purpose is to improve machinability, stabilize size and reduce hardness ,residual stress and deformation and crack tendency. It helps to refine grain, adjust micro-structure and eliminate micro-structure defects.

4 Tempering

Tempering is to reheat the quenched work-piece at the appropriate temperature which is lower than the critical one. After a period of heat preservation , the work-piece will be cooled by air, water, oil and other media. Under some circumstance, there will be two or several tempering.

After heat treatment , metal can realize the improvement of mechanical properties, the elimination of residual stress and the improvement of metal machinability.

Tel: +86-577-67926789 / +86-577-67927781

Tel: +86-577-67926789 / +86-577-67927781 E-mail:

E-mail: