SEDELON Technical Data Sheet

Choose Seat Material for Ball Valves

PTFE (RPTFE/PPL) series

Choosing the appropriate valve seat material is the most challenging decision in the selection of ball valves.

SEDELON Ball valves are available in a variety of seat and sealing options for a variety of general and specialty services. Soft-seat ball valves are factory shut-off tested and built to last.

PTFE is the most chemically resistant of all plastics. It also has excellent insulation and electrical insulation properties. PTFE has lower mechanical properties compared to other engineering plastics, but its properties are still useful over a wide temperature range (-100°C to 204°C, depending on brand and application)

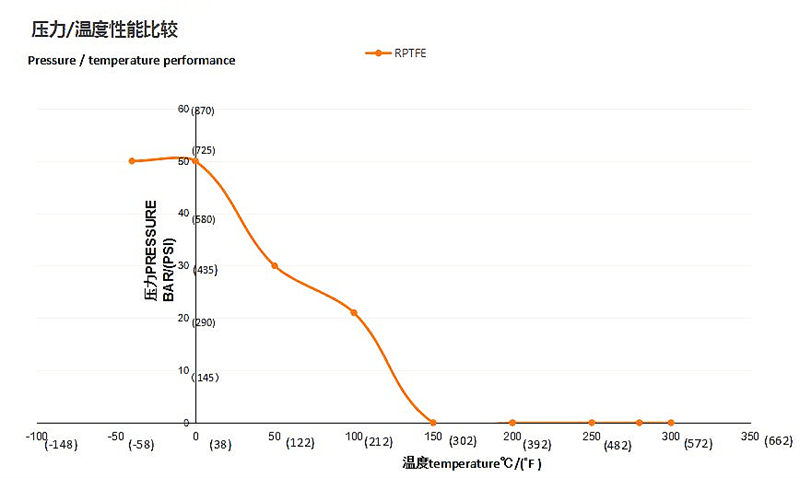

RPTFE is blended with selected percentages of fiberglass boilers to improve strength and wear resistance, cold flow properties, and permeability in formed valve seats. Reinforcement allows application at higher pressures and temperatures compared to unfilled TFE. Typical temperature range is -60C to 232°C. RPTFE should not be used in applications that attack glass, such as hydrofluoric acid and high temperature, highly corrosive substances. RPTFE is made by adding at least 15% fiberglass to Teflon and has a higher pressure-temperature rating than Teflon. RPTFE also has better cycle life than PTFE.

RPTFE molding method: mixing - molding - sintering - machining

The main application range of RPTFE on valves:

1. 150lb-300lb floating/fixed ball valve seat/sealing ring.

2. Temperature: -100°C ~120°C.

3. Packing/gasket (-250℃ ~260℃ ).

4. Sealing rings for other types of valves.

Tel: +86-577-67926789 / +86-577-67927781

Tel: +86-577-67926789 / +86-577-67927781 E-mail:

E-mail: