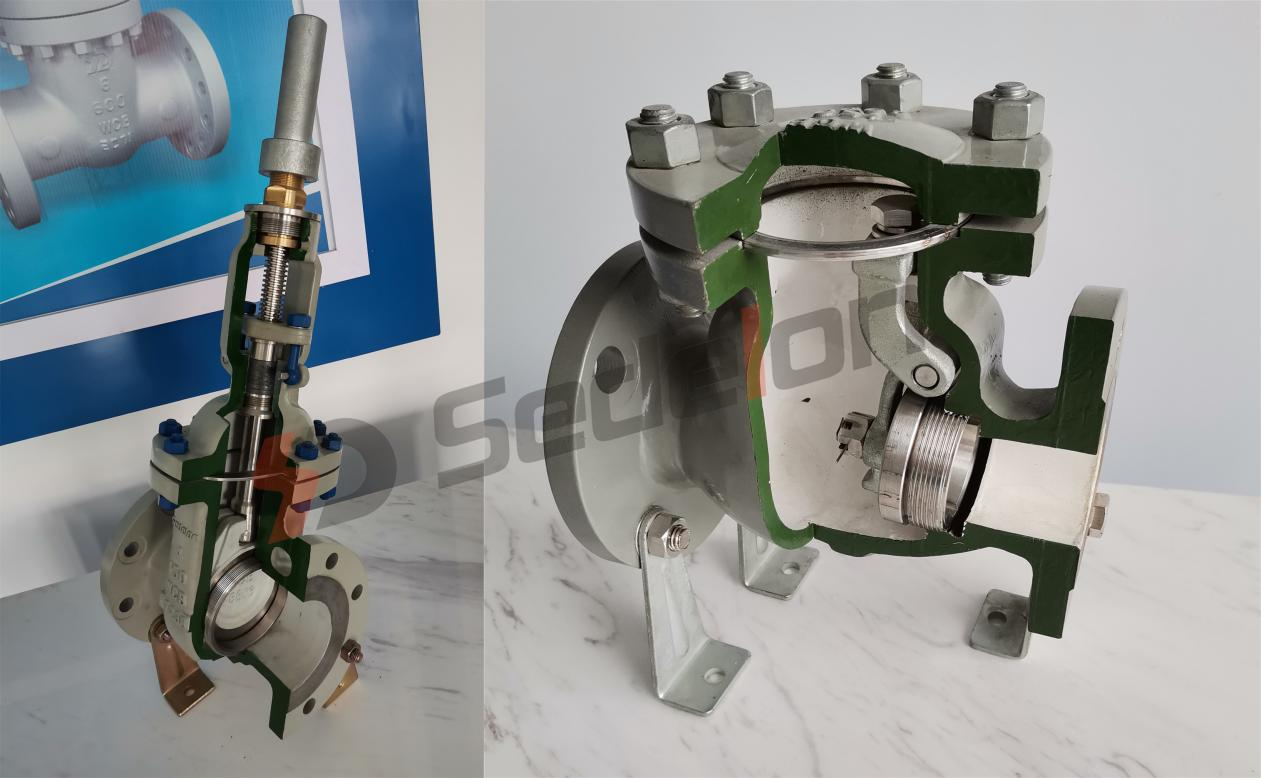

A dual plate check valve is a type of check valve that consists of two spring-loaded plates that are hinged together and positioned within the valve body. When the fluid flows in the forward direction, the plates are pushed open, allowing the fluid to pass through. However, when the fluid flows in the reverse direction, the plates are forced shut by the pressure of the fluid, preventing backflow. This type of valve is commonly used in applications where backflow prevention is critical, such as in water treatment plants, oil and gas pipelines, and chemical processing plants.

Sedelon received an order for over 1000 female threaded plug valves. The valve specifications are as follows: Body: ASTM A216 WCB Nominal Size: 2-1/2” Nominal Class: 300LB Connection ends: FNPT Operation: Lever

Sedelon Valve manufacturing custom basket strainer. The basket strainer is equipped with 2 sets complete gate valves as drain and vent valves, as well as handwheel, which can be opened directly to replace the screen. The basket strainer paint color is RAL9006, corrosion resistant.

During the use of pneumatic valves, it is usually necessary to configure some accessories to improve the performance of pneumatic valves or improve the use efficiency of pneumatic valves. Common accessories of pneumatic valve include air filter, solenoid valve, limit switch, electric positioner, etc. In pneumatic technology, the combination of air filter, pressure reducing valve and oil atomizer is called pneumatic triplet.

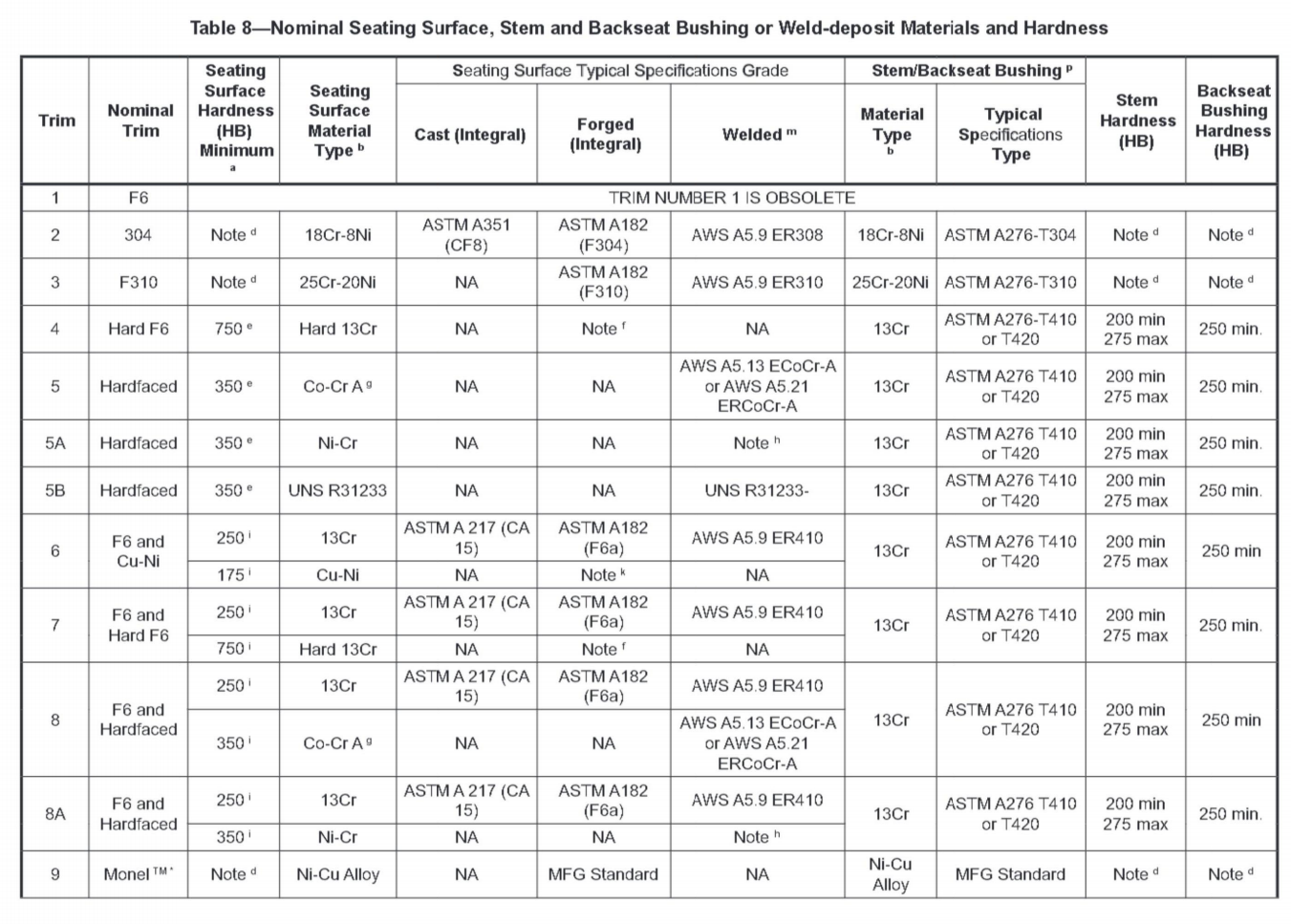

Valves seating surface performance has direct affection on the valve service life, due to it’s easily damaged by corrosion, erosion and wear of the medium during the continual opening and closure operation. The basic requirements for the seating surface is to ensure the sealing performance safe and reliable under the specified working condition.Below are the basic characteristics that a suitable seating surface should possess

When the medium is steam and hot water, it need to pay special attention to valves insulation measures.

Sedelon is a professional manufacturer of bronze gate valves. Our bronze gate valves are of high quality and high user satisfaction. Bronze gate valves are preferred by many sectors due to their strengths: simple structure, small fluid resistance, wide applications, labor-saving operation, etc. In addition, the sealing surface is subjected to less scouring and erosion by medium. Generally, they are suitable for water, seawater, oil, steam and other media. Bronze gate valves are mainly applied to severe in harsh working conditions that are required to withstand strongly corrosive environment. For instance, they are generally used in desalination platform and offshore drilling platform.

During the application of stainless steel knife gate valve, if there is a leakage problem, it will affect the usage of the valve. Different leaks require different solutions.

The closure part of ball valve is a ball which can rotate around the stem axis 90 degree to realize the purpose of opening and closing.

The seal face is of great significance of valves, and the quality of it directly affects the service life of valves. In addition, the material of seal face is an important element to ensure its quality. Therefore, there are five factors when choosing valve seal face material.

In 2022, the COVID-19 rebounded in various regions of China. Fortunately, there is no confirmed case of COVID-19 in our district so far.

Thanks for our customers' continuous support. These big size gate valves are delivered recently.

Tel: +86-577-67926789 / +86-577-67927781

Tel: +86-577-67926789 / +86-577-67927781 E-mail:

E-mail: